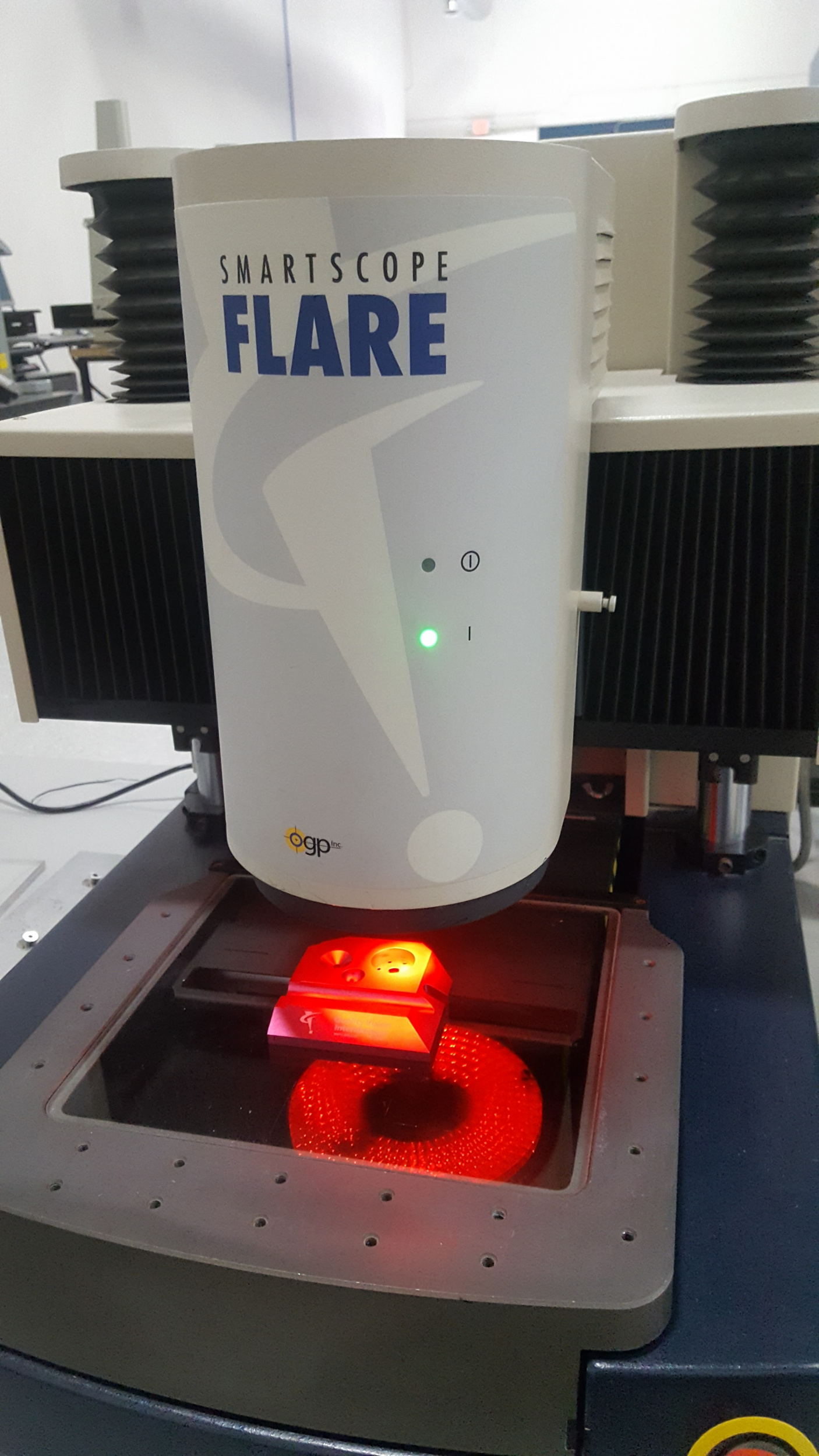

Offering machine installation and training as well as software training, support and service packages to enable you to maximise your inspection throughput. This machine appears to be complete with the exception of the joy stick. OGP UK has a dedicated team of highly-trained industry experts on hand to support you, with ISO9001:2015 accreditation, our service and applications engineers deliver the highest standards of service and support to meet the needs of our customers. About the SmartScope Flash 200 Optional touch probe, feather. Our non-contact measurement systems measure every feature faster than conventional methods, eliminating human error and providing accurate repeatable data collection whilst improving flexibility in your measurement processes.Īs the UK representative of OGP in the UK, we not only supply CMM measuring equipment nationwide but also deliver uncompromising excellence in service and support to all of our customers. A single OGP SmartScope®system uses multiple sensors and probes to complete the work of several machines, offering an improved speed of complex component inspection in one swift routine. OGP advanced multi-sensor measurement equipment meet all of your metrology requirements in one solution. The bottom line?īy using OGP multi-sensor technology, you get more part information, which leads to improved parts and processes,Īnd yields better quality – the quality your customers expect.One System, One Solution - For All Of Your Metrology Needs Operators will also only need to use one metrology software package cutting training costs and maximizing efficiency. Operators will only need to do one setup. Package you will lower your utility costs and use less floor space. OGP SmartScope video and multi-sensor systems are an all-in-one Measurement machine makes it a multi-sensor machine. OGP Smartscope Vision Multi Sensor Measuring System OPTICAL GAGING (M) SDN BHD A Leader In Non Contact Measuring System Co. Combining any of these 3D measurement sensors on a single Innovative technologies to measure very small features. New micro-probing technologies, such as the OGP Rainbow Probe and Feather Probe, use OGP Laser scanners measure using optics and detectors to capture laser light For example, OGP SmartScope video multi-sensor systems use cameras to image a part,Īnd then measure the image. Non-contact sensors don't actually touch a A sensor that applies pressure toĪ part – like the familiar touch probe – is a contact sensor. Sensor technologies can be contact or non-contact.

A sensor collects data points from a part to perform a measurement – it's the probe or detector SmartScope SP optics combine a wide field objective lens, digital zoom, and 5 megapixel monochrome digital camera, providing a distortion-free 16 mm diagonal field of view at low zoom, with high resolution at high zoom. All measurement systems uses at least one sensor Or what impact it can have on your manufacturing process.

If you are new to metrology it may not be obvious what a multi-sensor system is, how it is used, Get 3D measurement data with a single set-up, a single measurement routine, and using just oneįixture saving you time and improve your productivity. Video and multi-sensor systems are proudly made in the USA. Optical Gaging Products is the world leader in multi-sensor metrology and all SmartScope

They can combine non-contact video, touch probe, laser and white light. That accommodate parts of many sizes, in benchtop and floor models with capabilities to satisfyĮngineering, development, and production requirements. OGP Smartscopes are widely regarded as best in class multi-sensor measuring machines. OGP offers a variety of video and multi-sensor metrology systems Add touch probe, laser and micro-probes and its a full-fledged multisensor measurement system. Reliability, ease-of-use, and speed are all critical factors when SmartScope Flash 200 is a great video measuring machine. Today, metrology systems must exceed the demands of manufacturing.

0 kommentar(er)

0 kommentar(er)